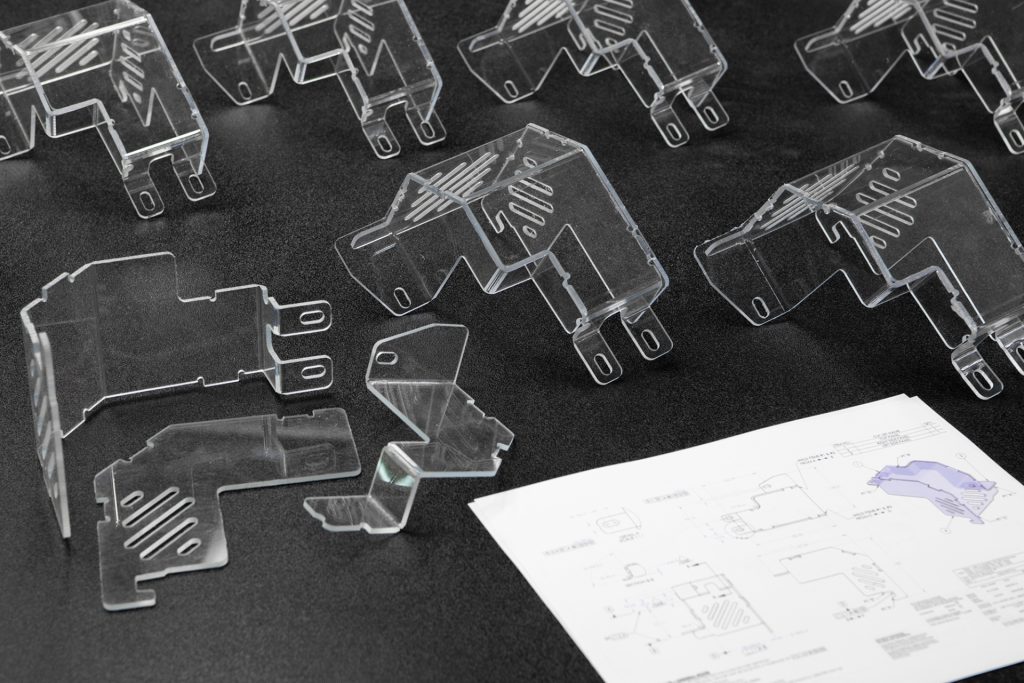

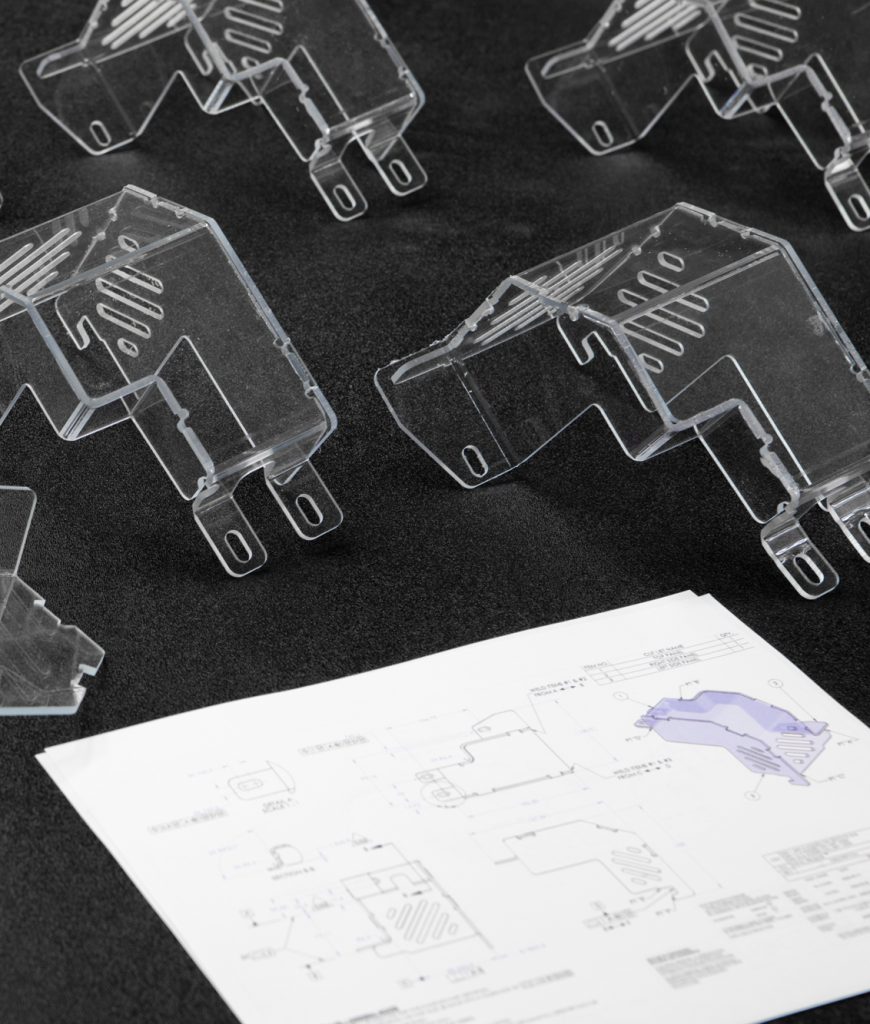

Assembly involves taking multiple plastic or metal components and joining them together to obtain a final piece. This process includes at least one additional transformation: the method used for the assembly, such as welding, bonding, press-fit, custom-cut parts, etc. It is through this process that custom displays are created.

Assembly techniques vary, each offering specific advantages based on the project's requirements. Bonding is ideal for assembling plastic parts, offering design flexibility while maintaining robust adhesion. Welding, on the other hand, is commonly used for joining metal components, ensuring a strong and durable bond. Press-fit, an adhesive-free assembly method, allows for the mechanical connection of components through the insertion of pins, thus without thermal stress. Finally, custom cutting provides maximum precision to create customized products that meet the strictest specifications.